eSimGathering TM

Condensate Inventory Management

With the shale plays producing higher volumes of condensate, and condensate prices being strong relative to other NGL’s, condensate has become a much larger portion of midstream revenues. However, accurate measurement of condensate and nuisance liquids in gas pipelines is problematic:

Actual measurement is costly (turbine meters, etc..)

Physical phenomenon disruptive (evaporation, flashing, etc..)

Due to high value, human integrity issues can come into play (risk of loss)

This necessitates the need for accurate, auditable, accountability of the condensate business process.

Further, once condensate data is entered by Field Operations, the balance of the condensate volume tracking process is often highly disjointed with the same data being manually entered into multiple spreadsheets and database applications (measurement, accounting, marketing, EH&S, etc.). This reduces organizational efficiency, increases the risk of errors, and increases the risk of losses across the system.

eSimulation developed the cloud-based Condensate Inventory Management system to automate and manage the entire condensate business process. The solution provides a central decision platform that all groups can use to manage the condensate business – EHS, Field Operations, Plant Operations, Engineering, Marketing, Accounting, Measurement, and Analytics.

Greenhouse Gas Emissions Reporting

The Greenhouse Gas Reporting package significantly reduces the manpower associated with meeting the regulations associated with EPA 40 CFR Part 98.230 Subpart W (Natural Gas Gathering and Boosting). It provides a mechanism for Field Operations to enter blowdown and vent data, calculates volumes based on segment dimensions, integrates gas analysis data from the measurement system, and generates all the reports required to manage the business. Most importantly, it compiles the necessary Subpart W reporting information, which can be submitted directly or integrated into your existing environmental reporting package.

eSimulation updates the software regularly to reflect significant regulations, which minimizes your compliance costs.

Pig Tracking

Piping Inspection Guage (PIG) tracking captures and stores critical information on pipeline operations, providing another data source on the state of the gathering system. The Pig Tracking application adds value by documenting these KPIs:

- Location identified by pipeline segment name or number

- PIG launch and receive date/time

- Chemicals injected

- Volume of liquid recovered

- Inspection results

- Sample(s) taken

Oil and Gas Volume Tracker

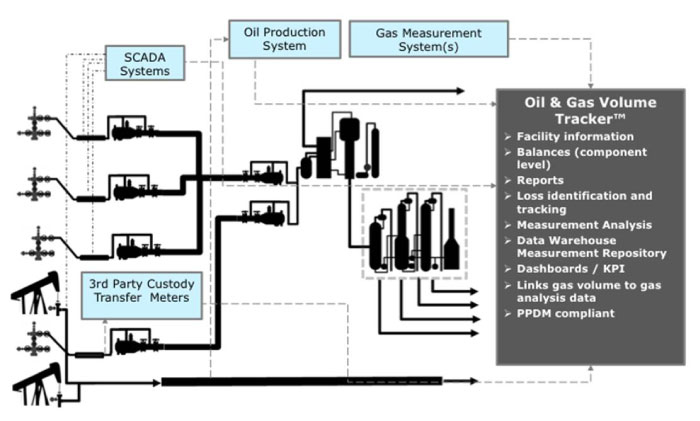

The Oil and Gas Volume Tracker equips upstream and midstream operations with these powerful capabilities:

- Captures product volumes from gas measurement systems, SCADA systems, and plant control systems.

- Matches volume data with composition data and provides a central repository for measurement data.

- Provides detailed volume and component balances across gathering systems, including condensates.

"Enable Midstream has invested in the [eSimulation] rigorous optimization infrastructure required to identify and capitalize on market opportunities as they become available. The solution has been shown to provide value to Enable Midstream under all processing conditions."

Alan Dove, et. al.

Former Sr. Manager Plant Services

Enable Midstream Partners

"*" indicates required fields