Value for Engineering

eSimulation provides tools that aggregate information on operations and facilities from multiple sources, track product inventories and losses, and optimize plant and equipment performance.

Increase Return-On-Assets Through Engineering Insights

- Increase Return-On-Assets Through Engineering Insights

- Capture plant data – temperatures, pressures, flows, analyzer signals, etc. – for visualization and analysis

- Identify problems before they become production losses by monitoring equipment system-wide

- Optimize plant performance with a rigorous optimization model – suggest setpoints to operators

- Compare downtime events and batch datasets to identify patterns and replicate best practices

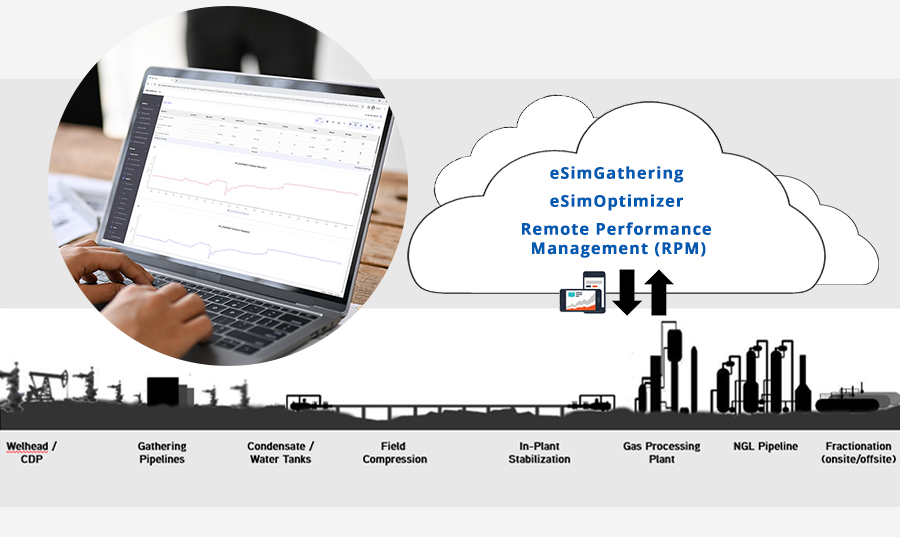

eSimulation starts with several off-the-shelf products that are ready to be configured to the operational requirements, including:

- eSimGathering – product tracking, loss accounting, and management

- eSimOptimizer – rigorous, open or close-loop gas plant optimizer for operation

- Remote Performance Management (RPM) – active data historian and reporting from multiple sources in one location

Together, the above tools deliver a strong project ROI; however, where needed, eSimulation also builds on these and other solutions by integrating 3rd party systems and applications into a seamless digital environment for operations.

"The Crane [plant] optimization project provided a strong Return on Investment for BP and a significant increase in Operational Profitability…”

Jan Estal Maberry

former Plant Engineer

BP, et.al

"*" indicates required fields